|

AoFang Transmission Machinery Co., Ltd.

|

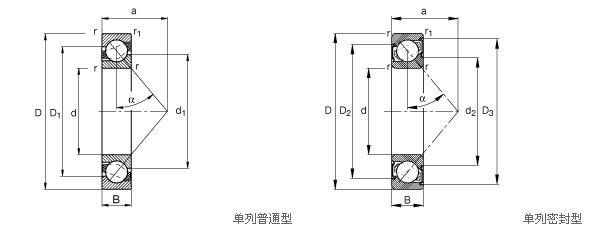

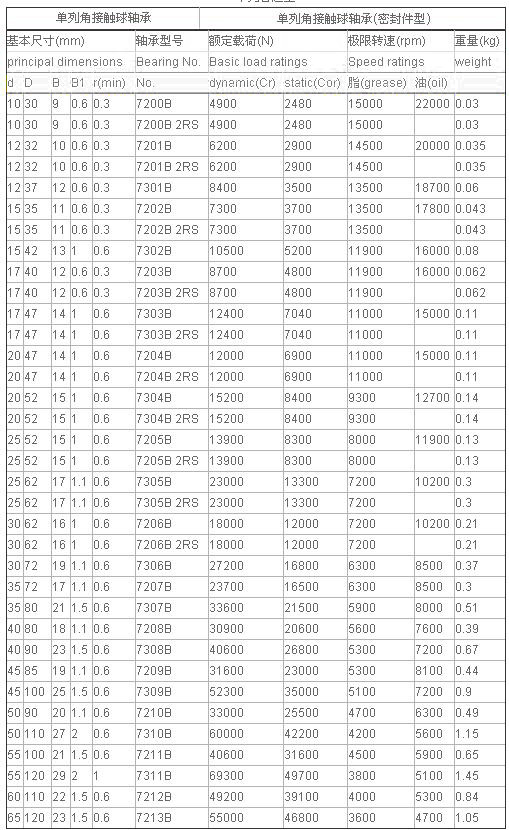

Single row angular contact ball bearing

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Angular contact ball bearings can bear radial load and axial load. Able to work under high speed.

Angular contact ball bearings can bear radial load and axial load. Able to work under high speed. The greater the contact angle, the higher the axial load-bearing capacity. Inside and outside their circle Raceway axis in the level of relative displacement, it can bear the radial load and axial load - the joint load (single row angular contact ball bearings can only bear axial load in one direction, it is generally regular used to install in pairs). Usually high-precision bearings and high-speed contact angle from 15 degrees. Role in the axial force, the contact angle will increase. Single row angular contact ball bearings can only bear axial load in one direction, the radial load to bear, will lead to an additional axial force. Axis and can only be restricted or shell in the axial displacement in one direction. If the installation of double-pairs, so that the outer ring bearing a pair of relatively, that is, wide-side end face of wide and narrow side facing the narrow end. This will avoid the additional axial force, but also in both directions so that shaft or housing to limit the scope of the axial clearance.

Angular contact ball bearings are: 7000C-type (α = 15 °), 7000AC-type (α = 25 °) and 7000B (α = 40 °) of several types. Lock the bearing in the outer ring of the mouth, the general can not be separated from both inside and outside the ring, can withstand radial and axial load as well as the joint of the axial load in one direction. Bear axial load capacity of a decision by the contact angle, contact angle, and are subject to high axial load capacity. Limit of the shaft or bearing housing in a direction of axial displacement

Angular contact ball bearings are: 7000C-type (α = 15 °), 7000AC-type (α = 25 °) and 7000B (α = 40 °) of several types. Lock the bearing in the outer ring of the mouth, the general can not be separated from both inside and outside the ring, can withstand radial and axial load as well as the joint of the axial load in one direction. Bear axial load capacity of a decision by the contact angle, contact angle, and are subject to high axial load capacity. Limit of the shaft or bearing housing in a direction of axial displacement

Angular contact ball bearings inside and outside their circle Raceway in the level of the axis there is relative displacement, it can bear the radial load and axial load - the joint load (single row angular contact ball bearings can only bear axial load in one direction, therefore often used generally installed in pairs). Cage materials are brass, such as synthetic resin.

Related Search

Double Row Angular Contact Ball Bearing

Double Row Angular Contact Bearing

Angular Contact Ball Bearing

Double Row Angular Ball Bearing

Single Row Ball Bearing

Double Row Angular Bearing

More>>