|

AoFang Transmission Machinery Co., Ltd.

|

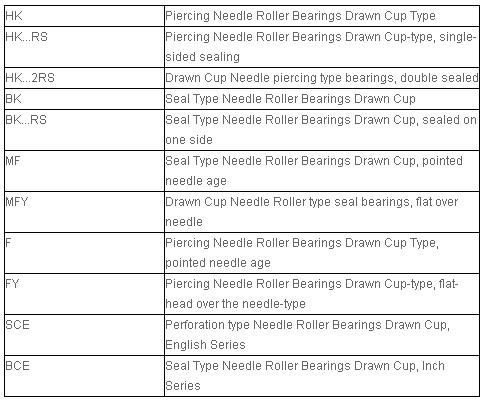

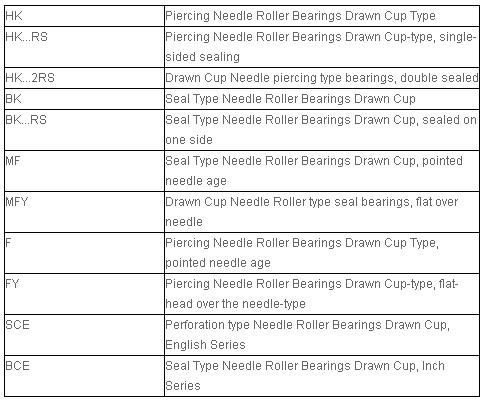

Drawn Cup Needle Roller Bearings (HK series, BK series, MF\MFY\F\FY\SCE\BCE series)

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Drawn Cup Needle Roller Bearings with outer ring of the bearing box used surplus with the rest, no axial fixtures.

Drawn Cup Needle Roller Bearings are precision sheet steel extrusion, the outer ring of 400-600 degrees by 1.3 degrees high temperature carburization of high toughness Cage guided needle group G2 group, and its radial cross-section very small, and with the overall load capacity, especially suitable for use in the economic category of a large number of products.

Drawn Cup Needle Roller Bearings with outer ring of the bearing box used surplus with the rest, no axial fixtures. Even in the high-speed, high load conditions, but also to ensure that their flexible working performance.

Drawn Cup Needle Roller Bearings advanced closure principle is that the body fat volume, and the long term without lubrication, as a result of high temperature lubrication intervals, thus ensuring its long-term worry-free operation.

Drawn Cup Needle Roller Bearings in general do not have inner circle, because of its design will normally be a reasonable choice of IR-type inner

Drawn Cup Needle Roller Bearings Bearings are divided into two ends of perforation (HK-type) and closed end bearings (BK-type).

Drawn Cup Needle Roller Bearings Bearing seal one end of a closed structure, applicable to shaft end and can withstand small Axial momentum

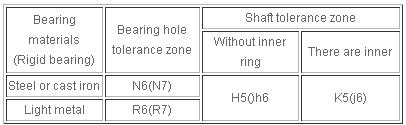

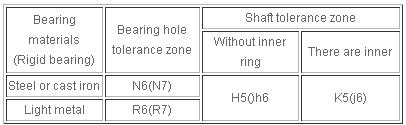

Installation tolerances:

Typically, a separate Drawn Cup Needle Roller Bearings without lubrication holes and double row bearings with lubrication hole is.

Installation tolerances table:

1. For the non-rigid bearing, tests need to be installed in order to determine the axis tolerances required to limit access to the work of the period gap.

2. Bearings cylindrical hole geometry in the numerical accuracy must be half of the range.

Only when the pressure bearing seat hole, the stamping of thin-walled outer ring to get the ultimate accuracy of the size and geometry. Hole size and the geometric precision of the decision bearing the inscribed circle diameter, precision and quality of support after installation. If the hole tolerance requirements can be selected according to Table 1, the bearing assembly to the rigid seat body, the needle diameter of inscribed circle in the approximate range of tolerance with F8. If the axis with a given tolerance of it, may be the work of the normal gap.

Drawn Cup Needle Roller Bearings _00.25mm width deviations

With the installation of assembly to be seated spindle hole pressure, the assembly axis spindle bearing shoulder should be marked with a code-phase of the installation process, can not be tilted so that bearing occurs.

Should be sufficient before assembly into the grease.

Test size:

As a result of the manufacture of thin-walled outer ring may not be in the circle, so Drawn Cup Needle Roller Bearings dimensional accuracy can not be tested before installation. Into only with the recommended pressure limits of tolerance bearing hole, the bearings in order to achieve the necessary geometric precision. Therefore, the following method should be tested size.

1. To the wall thickness of the bearing pressure ≥ 20mm, aperture table to make 2-inch line with the standards set in the ring;

2. With cylindrical plug inspection, clients can pass into the needle by virtue of their self-inscribed circle, the only side can not enter.

Check the size of table:

Drawn Cup Needle Roller Bearings with outer ring of the bearing box used surplus with the rest, no axial fixtures. Even in the high-speed, high load conditions, but also to ensure that their flexible working performance.

Drawn Cup Needle Roller Bearings advanced closure principle is that the body fat volume, and the long term without lubrication, as a result of high temperature lubrication intervals, thus ensuring its long-term worry-free operation.

Drawn Cup Needle Roller Bearings in general do not have inner circle, because of its design will normally be a reasonable choice of IR-type inner

Drawn Cup Needle Roller Bearings Bearings are divided into two ends of perforation (HK-type) and closed end bearings (BK-type).

Drawn Cup Needle Roller Bearings Bearing seal one end of a closed structure, applicable to shaft end and can withstand small Axial momentum

Installation tolerances:

Typically, a separate Drawn Cup Needle Roller Bearings without lubrication holes and double row bearings with lubrication hole is.

Installation tolerances table:

1. For the non-rigid bearing, tests need to be installed in order to determine the axis tolerances required to limit access to the work of the period gap.

2. Bearings cylindrical hole geometry in the numerical accuracy must be half of the range.

Only when the pressure bearing seat hole, the stamping of thin-walled outer ring to get the ultimate accuracy of the size and geometry. Hole size and the geometric precision of the decision bearing the inscribed circle diameter, precision and quality of support after installation. If the hole tolerance requirements can be selected according to Table 1, the bearing assembly to the rigid seat body, the needle diameter of inscribed circle in the approximate range of tolerance with F8. If the axis with a given tolerance of it, may be the work of the normal gap.

Drawn Cup Needle Roller Bearings _00.25mm width deviations

With the installation of assembly to be seated spindle hole pressure, the assembly axis spindle bearing shoulder should be marked with a code-phase of the installation process, can not be tilted so that bearing occurs.

Should be sufficient before assembly into the grease.

Test size:

As a result of the manufacture of thin-walled outer ring may not be in the circle, so Drawn Cup Needle Roller Bearings dimensional accuracy can not be tested before installation. Into only with the recommended pressure limits of tolerance bearing hole, the bearings in order to achieve the necessary geometric precision. Therefore, the following method should be tested size.

1. To the wall thickness of the bearing pressure ≥ 20mm, aperture table to make 2-inch line with the standards set in the ring;

2. With cylindrical plug inspection, clients can pass into the needle by virtue of their self-inscribed circle, the only side can not enter.

Check the size of table: